The Tamarind Village is a luxury apartment commune situated along the banks of Tudor Creek in Mombasa, Kenya. It is located directly adjacent to the famous Tamarind Restaurant opposite The Old Town. In September 2017, severe storm weather caused a catastrophic failure of the sea wall, resulting in its collapse in front of the harbour restaurant. Extreme rainfall rapidly caused peak stormwater discharges and water run-off was only made worse by the ground that had already been saturated by rain in the weeks before. The 40m collapsed embankment had a blocked stormwater drain buried beneath the surface. Hydraulic pressure built up behind the existing concrete wall, finally exceeding it’s ability to retain the pressure. The existing foundations of the restaurant were left exposed leaving part of the building on a cantilever and at great risk of further structural damage. Emergency works were undertaken to temporarily protect the eroded embankment while the stakeholders sought for a permanent solution to restore and reinforce the banks.

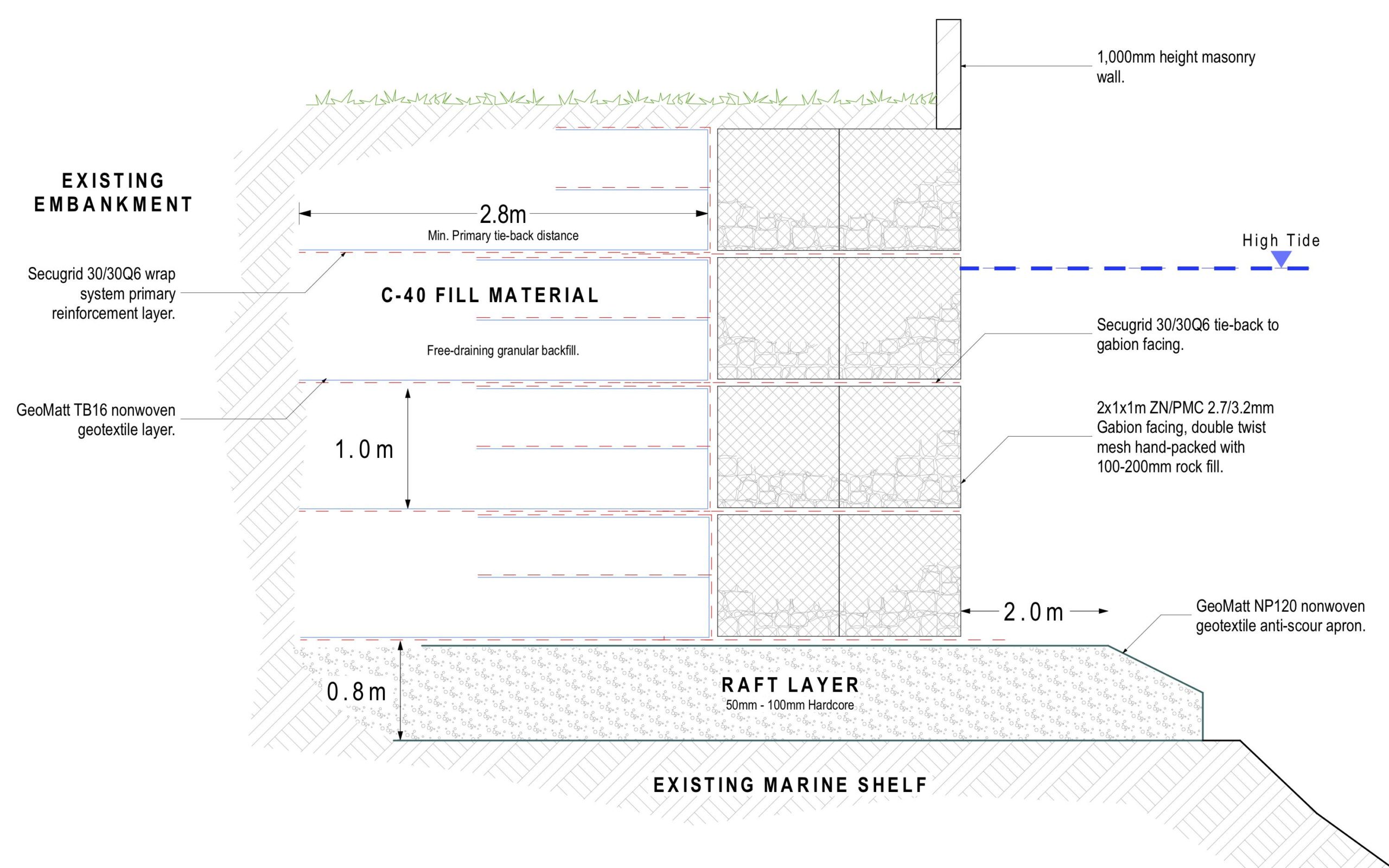

The solution implemented consisted of a robust, economic and free-draining structure with a vertical height of 4m. A Secugrid earth reinforced retaining structure using the ‘wrap’ system with polymer coated gabion armoured facing was employed. The Secugrid ‘wrap’ system allowed the retaining wall to be reconstructed at 90degree; a vertical wall to rehabilitate the maximum plot frontage lost to erosion. The secugrid wraps were lined with a nonwoven geotextile; GeoMatt TB16, to prevent migration and wash out of fine soil particles under hydraulic action. A heavy robust geotextile, NP120 was used in the foundation and toe of the structure to withstand the coarse coral reef base 2m below the water level, to provide a stable, level base and to limit undermining by the creek tidal current. The gabion facing element provides high performance hydraulic erosion protection and UV protection for the Secugrid reinforced retaining wall. The 2x1x1m gabions used in the facing element are made from high quality steel wire which is heavily galvanized to provide long term corrosion protection. An additional polymer coating was applied to give superior protection in more aggressive marine environments and give a longer design life.

Geotextiles East Africa was approached by the project engineer to provide a geosynthetic solution to this problem. Initially the structural engineer was inclined to rebuild a similar concrete retaining wall as was originally present. However, the owners of the Tamarind establishment had concerns regarding access to the waterfront for plant & equipment as well as the noise that would ensue at the start of construction. Considering the serene living environment, a creative solution was highly desired so as not to disturb the peace of residents.

The Maccaferri gabions engineered from double-twist hexagonal woven steel wire mesh, and in this case, with additional polymer coating were delivered flat-packed. The gabion boxes were assembled and filled with rocks between 100-200mm at the project site. This was done with manual labour, without any need for concreting works, allowing for a discreet and steady installation process. The gabion wall forms a permeable, monolithic facing for river bank protection and channel linings for erosion control.

Being made of flexible double twisted wire mesh, the gabions can accommodate differential settlements without sustaining damage, unlike rigid or impermeable structures such as concrete or masonry walls. Another important criteria for choosing the most appropriate solution included:

1. Project Costs

2. Construction feasibility in terms of local conditions (e.g. operating between high & low tide, space constraints, access)

3. Time

4. Local planning approvals (both project design and materials to be used in the construction).

The weak parameters of the existing soil, together with the potential further erosion of the collapsed embankment with each high tide, required urgent reinforcement. Secugrid 30/30Q6 was selected as the primary reinforcement material. It provided a quick and relatively low-cost solution in terms of ease and speed of contruction as well as a low ecological impact in the coastal environment.